Predicting Profitable Production Processes

Whenever I think about the questions I'm asked to answer in operations - how long will something take, when can we ship this product, why are we spending more on labor this month - I'm always grateful when I have some record of the team's activity handy.

In today's data-driven world, companies have developed an expectation of perfect accuracy at a moments notice for any answer in response to any question. And why shouldn't managers expect this now? The tools at the disposal of even the most forward of front-line workers today make data collection an easily achievable reality.

This data that gets collected used to be locked away - and still is in the vast majority of businesses - in the minds of highly experienced individuals who have worked at the same job for decades. As our workforce has become more transient, the need for companies to capture this information and build upon it with each successive employee has only grown. I detail my thoughts on the best way to do this here.

Thanks for reading The Value Add! Before continuing to read, please take a quick second to subscribe for free to receive new posts.

The point of a route

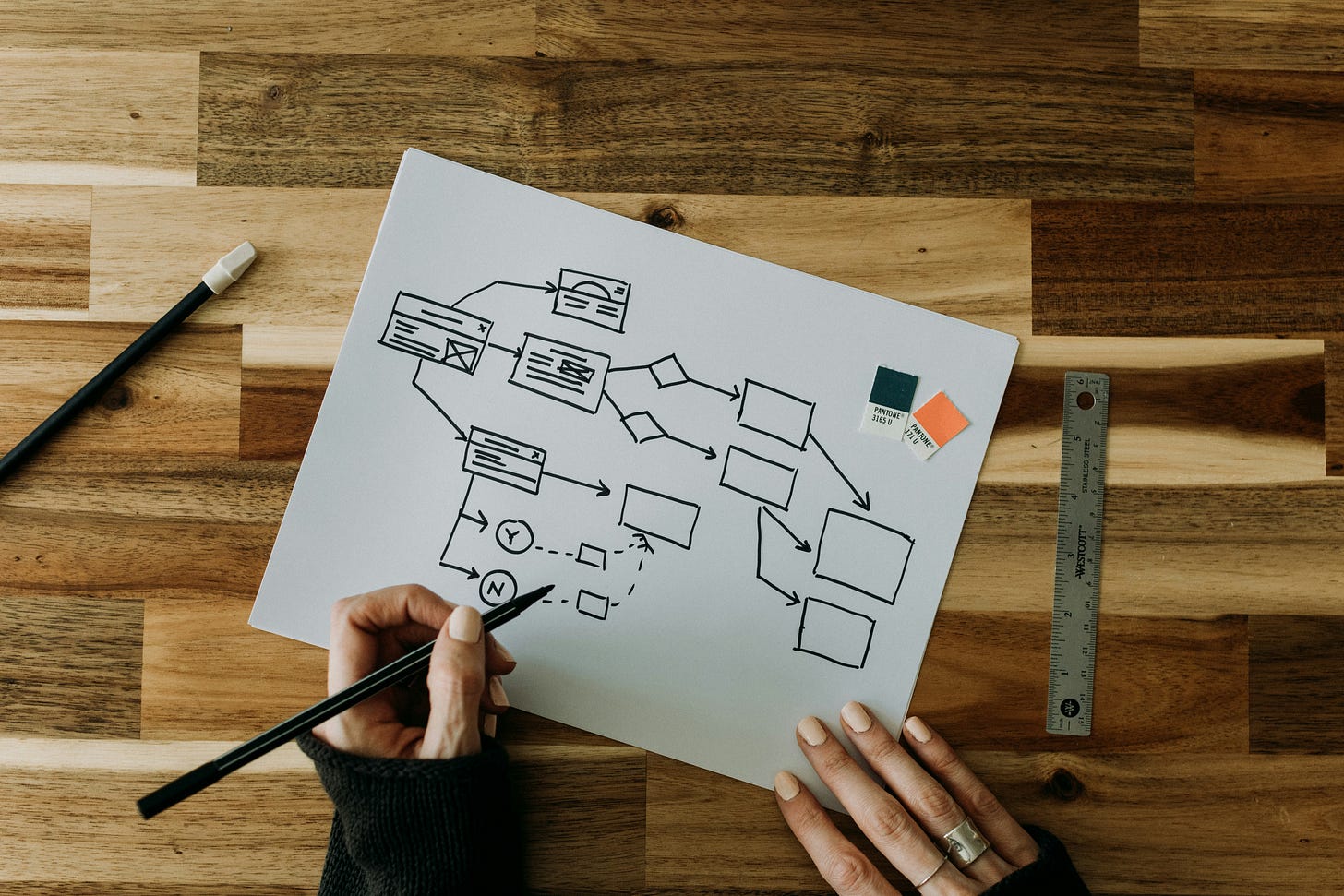

This is where the route comes in. A production route (or routing or router) is a collection of operations that define the standard sequence of steps towards completing a product or an activity. Manufacturing companies use routes to establish baselines and keep track of their performance in relation to their budgets.

The route adds structure to an often complex series of tasks that have various amounts of interdependence. The degree to which the structure is desired depends entirely on the aims of the company along with a host of other factors (ie their industry, business model, regulatory environment, etc…).

Most importantly, a route allows all layers of management to answer questions about the physical world through data, which is in essence the promise of Industry 4.0. Need to know who your top performers are? Check your actual assembly times compared to the standards in the route. Need to know what lead time to quote a customer? Check your capacity charts that base their numbers on standard routed hours.

Modeling considerations

We can consider these questions to be a subset of the primary drivers of how we should set up our route’s structure. The level of detail we expect to be able to answer will first determine what granularity we want to build out our routes to. This might be the same for all products, or maybe we take different approaches on a case by case basis.

The next decision we need to make revolves around the resources we are willing to devote to the maintenance of these routes. Nothing in this world is free so having a firm grasp on the skills and hours it will take to set up the routes, and then maintain them over time, is foundational. Organizations need to balance their need for information with the cost of having access to it and then adjust their expectations accordingly.

Lastly, the organization’s culture plays a tremendous role in how successful the chosen model will be. If an organization cares about detail, but the model does not allow for that, adoption will be low and people will find a way outside of the system to maintain the data they need - the reverse being true as well. Ultimately, the model must serve those who will use the information every day, and at the very least, shouldn’t work against them.

A route’s structural needs

Once the general model has been agreed upon, the details of the structure need to be worked through. Is this a single operation route or is it more complex? Do we create one route for an entire product structure or one route per BOM level? Do we need to handle discrete items or are we creating a recipe?

Depending on the software being used, there will be certain limitations that we have to deal with. For example, are we able to represent scrap amounts natively in the route or do we need to find a hack to do so? Every software will be optimized (to varying degrees) for different use cases, so each will have its own unique set of limitations.

In no particular order, here are some of the major decisions that need to be made for each route, depending on its application:

Are we tracking duration?

Are we distinguishing between labor hours and machine hours?

Do we want to distinguish between types of hours further such as processing time vs setup time?

Do we want one big bucket of hours or granular operations?

Do we care what work center completes the work?

Do we want to produce batches or control production by lots?

Do we want to track actual values and compare them to standards?

Do we want to assign specific resources (people, machines, locations) to each operation?

Will operations need to be sequential, parallel, or a mix of both?

Do you need different versions of your route to be activated depending on different conditions?

and on and on and on…

The garnish

The list above is long, but by no means exhaustive. Every organization will have different needs specific to their business. There are also some less common needs that each system solves in a different way, but that might be value added to your organization. For example, material flow and inspection operations struggle to be thought of in the same way as traditional processing operations, even though every company has them.

When it comes to material flow, most ERP systems will have a warehousing or inventory management function included. This is how many programs consume material out of inventory or even control how its delivered to the production areas. But if there are interim steps for material delivery, or waste disposal steps, or packaging operations, that need to be completed by a different team, how will those steps be represented, seeing as pick and put functionality in warehousing modules is often not equipped to handle this.

Secondly, quality inspections can be included in regular routes, but there's usually an entire quality module that needs to be tied in to properly account for quality issues that arise in-process. Not every non-conformance is captured at the finished item level and the functionality for doing so throughout the route can be a nice way to represent your internal defects with greater precision.

The road to profit

Being that manufacturers create products through value-adding activities, tracking their operations through their ERP system is a great way to inform their decision-making process. Any amount of data is available if they are willing to invest in collecting it.

As we can see though, this process can become very complicated. Each business will have to decide what the return will be and whether or not that return justifies the investment. It’s clear that those who are successful in this stand to reap the rewards many times over.

Thanks for reading The Value Add! Subscribe for free to receive new posts.